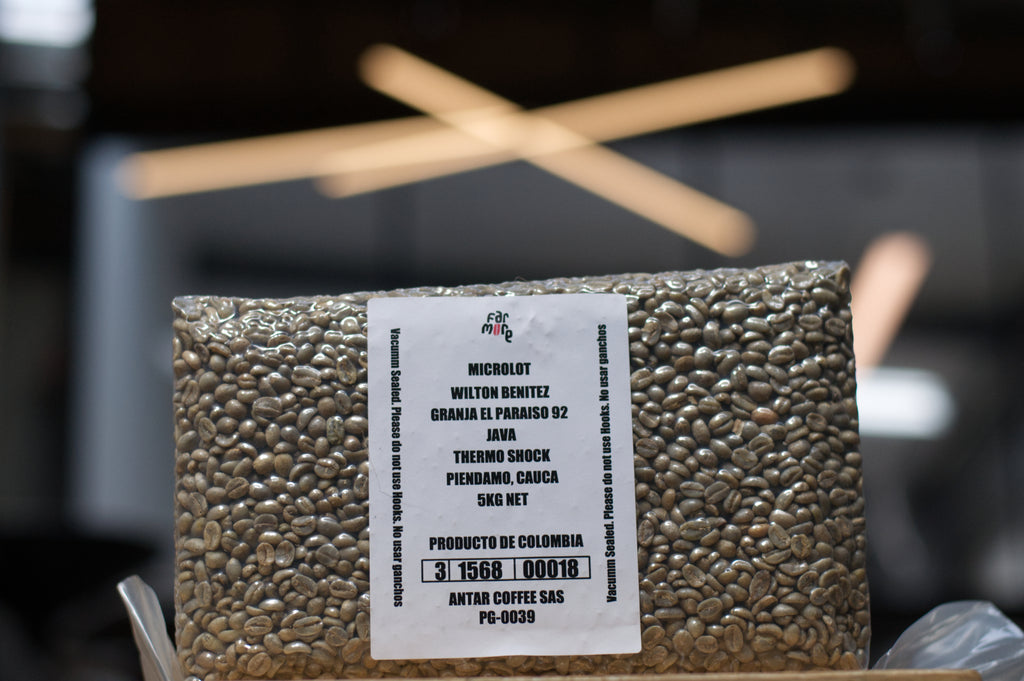

Select Series 010 - Wilton Benitez - Java (Thermo Shock)

Java (Thermo Shock) - Wilton Benitez

Here at Maker, we are all about bringing you special-tasting coffees with unique processing. Wilton Benitez of El Praiso 92 in Colombia is a former chemical engineer who has brought his skills to coffee processing. His processing plant is akin to a food production facility, where he can easily control the conditions subjected to his coffee. On-site laboratories provide an easy and convenient way to scrutinise the chemical composition of his product, allowing him to match yeasts from his collection with each coffee in order to arrive at his desired sensory qualities. Wilton has pioneered what he calls the ‘Thermo Shock’ process, and is able to produce clear and distinct flavours in an exceptionally clean cup.

Wilton’s Thermo Shock process is highly involved and controlled at every stage. Cherries are picked at a precise stage of ripeness, and chemically analysed to determine which yeast they will best pair with, depending on the desired outcome. These cherries are blanched in boiling water, similar to how we would blanch tomatoes before peeling or broccoli before freezing. This has a dual effect: sterilising the cherries of enzymes and microbes which may impart their own uncontrolled flavours, and removing pockets of air and water which may inhibit microbial access to the fermentation fuel in fruit flesh and mucilage. Next, the cherries are placed intact into a deoxygenated and sealed bioreactor, and left to ferment for two days. The cherries are then removed, pulped, and replaced in the deoxygenated bioreactor in mucilage, and then submerged and inoculated with the chosen yeast. This second fermentation stage lasts for five days.

Finally, the coffee seeds are removed and cleaned in warm water, and then experience the eponymous thermal shock with a cold water rinse. This is intended to ‘lock in’ the aroma compounds and flavours within the coffee seed. Additionally, this step sterilises the coffee again, and in Wilton’s words ‘removes the pollution’, in order to fortify the intended flavours and banish the distractions. Finally, the coffee is dried in a controlled environment down to approximately 11% to ready the coffee for export.

Wilton’s coffee is unique and offers strong flavours in a clean cup. We are proud to offer his coffees, as we know they will give you an unparalleled tasting experience.